Dr. Ha Yoon-Cheol’s team at KERI’s Next Generation Battery Research Center has developed an “enhanced coprecipitation method” that enables faster and higher-quality production of lithium superionic conductors for all-solid-state batteries (ASSBs). ASSB replaces the “electrolyte,” which transfers ions between the anode and cathode, with a solid instead of a liquid, significantly reducing the risk of fire or explosion.

Solid electrolytes are difficult to manufacture and expensive. However, in 2021, Dr. Ha Yoon-Cheol’s team garnered significant attention by proposing the “coprecipitation method,” which enables large-scale production of solid electrolytes through a one-pot solution process, without the need for expensive lithium sulfide (Li2S) by directly adding the raw materials into a single container.

This method significantly reduces raw material costs compared to conventional methods and does not require high-energy milling or evaporation processes. The technology has been transferred to Daejoo Electronic Materials Co., Ltd., a domestic company specializing in electrical and electronic materials.

Since then, KERI has continued follow-up research with KAIST, Daejoo Electronic Materials Co., Ltd., and others. Through these efforts, they successfully identified the detailed mechanisms behind the dissolution and coprecipitation phenomena, leading to the development of an optimized, upgraded coprecipitation method that significantly shortens production time and dramatically improves the quality of solid electrolytes.

-

Dr. Ha Yoon-Cheol’s team at KERI (right) has successfully developed a faster and higher-quality production method for solid electrolytes for ASSBs using the “upgraded coprecipitation method.” Credit: Korea Electrotechnology Research Institute

-

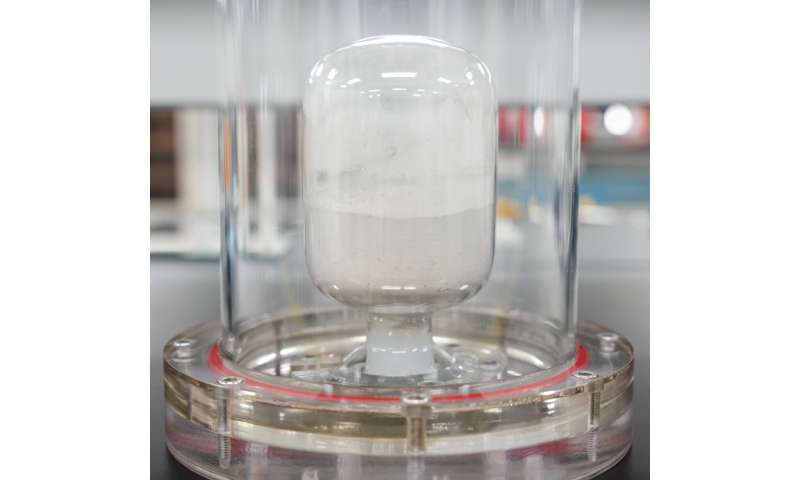

Solid electrolyte powder for ASSBs, synthesized using the “upgraded coprecipitation method” developed by Dr. Ha Yoon-Cheol’s team at KERI. Credit: Korea Electrotechnology Research Institute

The key to the coprecipitation method is the process of evenly dissolving the raw materials in a solution, precipitating them, and then filtering them out. Dr. Ha Yoon-Cheol’s team first mixed lithium, sulfur, and catalyst in the optimal proportions, and analyzed the process in which lithium polysulfides and lithium sulfide are sequentially formed depending on the degree of lithium dissolution.

They then applied this to the synthesis processes of three-element (such as Li3PS4) and four-element (such as Li6PS5Cl) solid electrolytes, developing a technology that enables rapid and homogeneous dissolution and coprecipitation of various raw materials.

The detailed mechanism analysis of KERI’s coprecipitation method was carried out by top researchers from leading universities in Korea. Professor Byon Hye Ryung’s team at KAIST led the chemical analysis of the intermediate species formed depending on the degree of lithium dissolution.

Additionally, quantum calculations and anion mass spectrometry conducted by Professor Baek Moo-Hyeon’s team at KAIST and Professor Seo Jongcheol’s team at POSTECH played a crucial role in uncovering the accurate molecular structures. Based on this, Daejoo Electronic Materials Co., Ltd. incorporated the technology related to continuous processes that will be applied in the actual mass production of solid electrolytes.

Through continuous collaboration between industry, academia, and research institutes, the upgraded coprecipitation method was developed, significantly reducing the production time of solid electrolytes from 14 hours to just 4 hours.

The quality of the optimally synthesized solid electrolytes has also been improved. Conventional manufacturing methods faced a persistent issue of lower ionic conductivity during the scale-up process. However, with the application of the upgraded coprecipitation method in the scale-up process, the ion conductivity of the solid electrolytes reached 5.7 mS/cm. This surpasses the level of liquid electrolytes (~4 mS/cm).

In addition, by applying the solid electrolytes to a 700mAh ASSB pouch cell, which is about one-fifth the capacity of a smartphone battery, an energy density of 352Wh/kg was achieved, surpassing the energy density of commercial lithium-ion batteries (270Wh/kg). Moreover, in experiments where the ASSB was charged and discharged 1,000 times, it maintained over 80% of its capacity, confirming its stable lifespan.

The research results were published in the journal Energy Storage Materials. The research team has confirmed that this technology can be applied not only to the synthesis of solid electrolytes but also to the production of various functional coatings. Recently, a patent for the technology has also been filed.

Dr. Ha Yoon-Cheol of KERI stated, “The previous achievement was significant in that it introduced the coprecipitation technology for the first time in the world to the manufacturing process of solid electrolytes, while this upgraded method is a result of optimizing the principles of the coprecipitation method through detailed analysis, leading to better outcomes.”

“This will serve as a key enabler for opening an era of mass production of ASSBs at a low cost.”

More information:

Mukarram Ali et al, Lithiation-driven cascade dissolution coprecipitation of sulfide superionic conductors, Energy Storage Materials (2024). DOI: 10.1016/j.ensm.2024.103938

Citation:

Faster and higher-quality production of lithium superionic conductors for all-solid-state batteries (2025, February 10)

retrieved 11 February 2025

from https://techxplore.com/news/2025-02-faster-higher-quality-production-lithium.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.