Korea imports 95% of its core minerals such as lithium, nickel, and rare earths. Rare earths, in particular, are characterized by chemical, electrical, magnetic, and luminescent properties that can be achieved by adding only a small amount, and their use has recently increased significantly as core materials in the eco-friendly automobile and renewable energy industries.

China, a major producer of rare metals, is controlling the supply through its strategy of weaponizing resources, putting great pressure on the domestic industry.

Dr. Jae-Woo Choi and his team at the Center for Water Cycle Research at the Korea Institute of Science and Technology (KIST) have developed a fiber-based recovery material that can recover rare earth metals such as neodymium (Nd) and dysprosium (Dy) with high efficiency.

The findings are published in the journal Advanced Fiber Materials.

The new material is expected to contribute to solving rare earth supply and industrial stability issues by recovering and recycling rare earth metals (neodymium-iron-boron (Nd-Fe-B)) that are mainly used in third-generation permanent magnets, which are essential components in the electric vehicle, hybrid vehicle drive motors, wind power, robotics, and aerospace industries.

KIST researchers have developed a nanostructured composite fiber material composed of metal-organic structures and polymer acryl fiber composite fibers to efficiently recover rare earth metals. The adsorptive material is based on acrylic fibers, which are already widely used in Korea, and is economical and productive.

The researchers expect that the developed material will be of great industrial use as it easily adsorbs rare earths from waste liquids while facilitating their recovery.

-

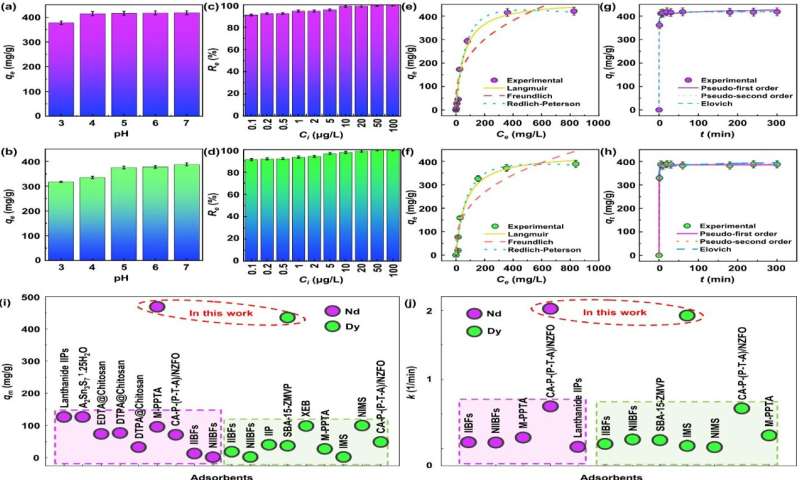

Rare earth metal recovery performance from fibrous materials / Effect of pH on the rare earth recovery performance of fibers for (a) Nd3+ and (b) Dy3+ ions. The initial concentration and adsorbent dosage for each rare earth metal ion were 1,000 mg/L and 0.5 g/L, and the reaction time was 24 hours without any pH adjustment. Recovery efficiency of the material for low concentrations of (c) Nd3+ and (d) Dy3+ ions. Isothermal equilibrium curves of the material for (e) Nd3+ and (f) Dy3+ ions. Contact time is 24 hours and performed without pH adjustment. Recovery kinetics curves of CSCF for (g) Nd3+ and (h) Dy3+ ions. Initial concentration is 1,000 mg/L and performed without pH adjustment. (i) Maximum recovery capacity (qm) of Nd3+ and Dy3+ of the adsorbent material and (j) recovery rate constant k compared to the adsorbents reported in the top papers. Credit: Korea Institute of Science and Technology

-

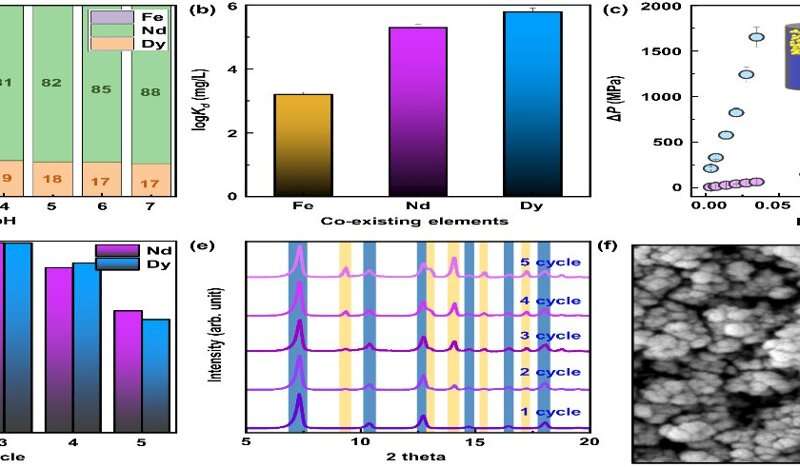

Superior industrial applicability of rare earth metal recovery fibers / Practical applicability of the recovery material to the process of rare earth recovery from discarded permanent magnets. (a) Plot of the composition of each ion as a function of pH for an initial concentration ratio of 65 (Fe):25 (Nd):10 (Dy). (b) Partition coefficients (Kd) for the adsorption performance of the fiber material for three metal ions, predicting selective rare earth recovery using the adsorption material. (c) The adsorption reactor filled with the adsorption material exhibits a significantly lower pressure drop (faster mass transfer rate) than the module filled with the same weight of granular powder. Internal images show reactors filled with each material. (D) The ratio of the initial maximum adsorption amount (QM) of the material before regeneration to the maximum adsorption amount after repeated regeneration (QM,R) is shown. Nearly 100% material regeneration performance is maintained up to 3 regenerations. (e) XRD pattern of NPZIF-8 after regeneration, showing the crystal structure collapse of NPZIF-8 after 4 regenerations. (f) Electron microscopy image of NPZIF-8 nanoparticles on the surface of CSCF adsorbent after 5 regenerations. (Scale bar: 1 μm). Credit: Korea Institute of Science and Technology

The developed fiber material showed adsorption capacities of 468.60 mg/g for neodymium and 435.13 mg/g for dysprosium, the highest in the world. This is significantly higher than conventional adsorption materials and can be applied to simple reactors, which can significantly improve the energy efficiency of the recovery process.

The team expects the material to be able to effectively recover rare earths not only from waste permanent magnets, but also from a variety of industrial wastewaters containing rare earth metals, such as mine drainage. In particular, its easy surface modification makes it applicable to a wide range of industrial wastewaters, and it is expected to become a technological alternative for securing rare metal resources.

“The high-efficiency rare earth metal recovery material developed in this study is a technology that can replace existing granular adsorption materials, showing excellent results in terms of performance, productivity, economy, and applicability, which will revitalize the digital infrastructure waste mineral extraction ecosystem, and has great potential for industrial application through resource recycling,” said Dr. Jae-Woo Choi of KIST.

“In the future, the technology can be expanded to selectively recover various useful resources, including rare earths, from industrial wastewater, contributing to carbon neutrality and rare earth-related upstream and downstream industries,” said Dr. Youngkyun Jung.

More information:

Youngkyun Jung et al, Synergistic Effect of Core/Shell-Structured Composite Fibers: Efficient Recovery of Rare-Earth Elements from Spent NdFeB Permanent Magnets, Advanced Fiber Materials (2024). DOI: 10.1007/s42765-024-00442-4

Citation:

Recovering rare earth metals from waste permanent magnets (2024, December 6)

retrieved 7 December 2024

from https://techxplore.com/news/2024-12-recovering-rare-earth-metals-permanent.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.