Over the past decades, robotic systems have been rapidly advancing, fueled by the continuous introduction of more advanced electronics, mechanical components and software solutions. As a result, robots can easily become obsolete and outdated as newer systems emerge.

Singapore University of Technology and Design recently introduced an approach for the continuous upgrading of soft robots, which could in turn reduce electronic waste originating from the field of robotics. This approach, introduced in a paper published in Science Robotics, relies on a three-dimensional (3D) printing strategy that employs a newly formulated gel.

“Our group has been actively researching soft robotics for several years, with a particular focus on developing innovative multi-material additive manufacturing techniques,” Pablo Valdivia y Alvarado, senior author of the paper, told Tech Xplore.

“Unlike traditional robots, soft robots present unique challenges when it comes to repair, often resulting in significant waste. For instance, when new functionalities emerge or a soft robot sustains severe damage, older prototypes are frequently discarded, much like consumer products.”

When reviewing previous research, Valdivia y Alvarado and their colleagues realized that sustainability has not yet become a key focus within the field of robotics. To address this lack of sustainability, the researchers devised a new approach that could extend the lifespan of various types of soft robots.

“As an added advantage, our approach can handle multiple materials, making it adaptable to consumer products as well,” said Valdivia y Alvarado. “We hope this innovation will not only advance soft robotics but also find broader applications in other devices, promoting sustainability across industries.”

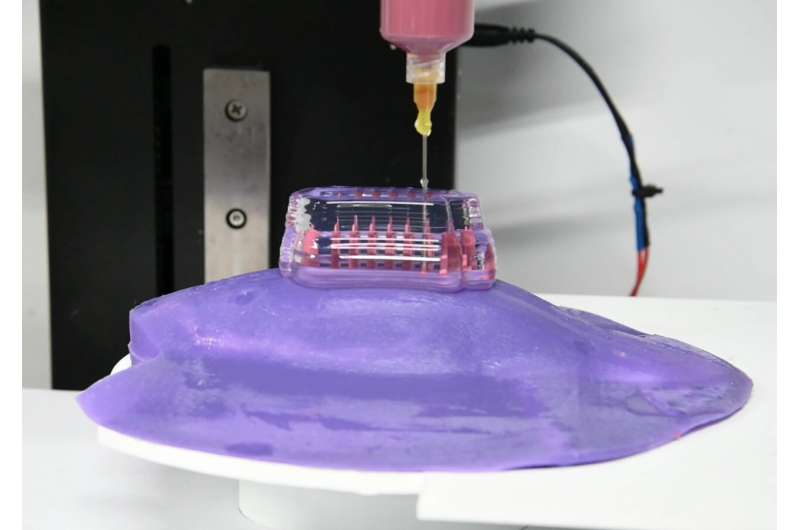

The new approach devised by the researchers relies on an innovative in-situ additive manufacturing process that can be used to repair and upgrade soft robots with high levels of precision and efficiency. The first step of this process entails the 3D printing of a gel support onto the targeted surfaces of the soft robot that needs to be upgraded.

“This gel is specifically optimized to maintain its shape under gravity, eliminating the need for a container,” explained Valdivia y Alvarado. “Once applied, the system prints multi-material components or features directly onto the robot’s surfaces covered by the gel. The gel acts as a stabilizing medium, securely holding the new features in place and ensuring stable curing. After curing is complete, the gel can be easily washed away with water, leaving the newly added features seamlessly integrated.”

Notably, the support gels utilized by Valdivia y Alvarado and his colleagues are highly versatile and compatible with various surfaces or materials. This means that their approach could be adapted and applied across various soft robots, and potentially also to other electronic devices.

To assess the potential of their approach, the researchers used it to upgrade a batoid-like soft robot, adding tactile sensors, a passive whisker array and actuated hooks. They also repaired parts of the robot’s synthetic skin that were torn and damaged by the whiskers.

In the future, this promising manufacturing process could be applied to other robots that are now viewed as outdated or damaged. It could also potentially be used to repair and upgrade other electronic systems, including smart appliances, smartphones and other devices.

“The key advantages of our approach include the broad material compatibility of the printable gel supports and its potential for significantly extending the life of soft robots,” added Valdivia y Alvarado. “Our group is now working on other new additive fabrication approaches that emphasize sustainability and material circularity for soft and material-based robotics.”

More information:

Elgar Kanhere et al, Upgrading and extending the life cycle of soft robots with in situ free-form liquid three-dimensional printing, Science Robotics (2024). DOI: 10.1126/scirobotics.adn4542

© 2025 Science X Network

Citation:

3D printing strategy can upgrade soft robots and extend their lifespan (2025, January 16)

retrieved 16 January 2025

from https://techxplore.com/news/2025-01-3d-strategy-soft-robots-lifespan.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.