Over the past decades, energy engineers have been developing a wide range of new technologies that could power electronic devices, robots and electric vehicles more efficiently and reliably. These include solid oxide cells (SOCs), electrochemical devices that can operate in two different modes, as fuel cells or as electrolyzers.

Fuel cells are devices that can convert the energy in specific chemicals into electricity via chemical reactions. Electrolyzers, on the other hand, are technologies that can split water (H2O) or other molecules using electricity, to produce hydrogen (H2) or other desirable chemicals.

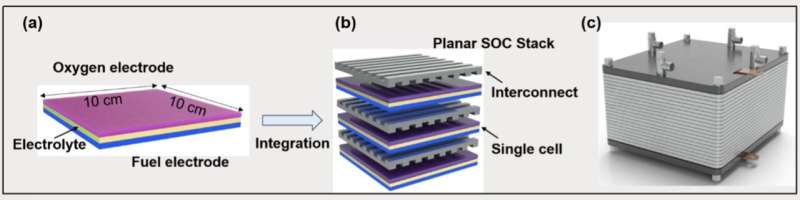

Most SOCs developed so far are two-dimensional (2D) and consist of flat structures with stacked layers of different materials. This 2D design, however, limits the extent to which the devices can be reduced in size while also increasing their weight, as it relies on metallic interconnects to enable the flow of energy and seal different components.

Researchers at the Technical University of Denmark recently designed new three-dimensional (3D) SOCs with a periodic surface structure known as a gyroid. These cells, outlined in a paper published in Nature Energy, can be fabricated using 3D printing, also known as additive manufacturing.

“The use of gyroid structures in heat exchangers has been shown to reduce weight, improve compactness, and increase efficiency,” Prof. Vincenzo Esposito, corresponding author of the paper, told Tech Xplore. “We replace the metal with an ion-conducting ceramic, thereby realizing the 3D-SOC concept. The 3D-SOC is well-suited for applications that demand lightweight construction, compactness, and stability, such as those in the aerospace and automotive industries.”

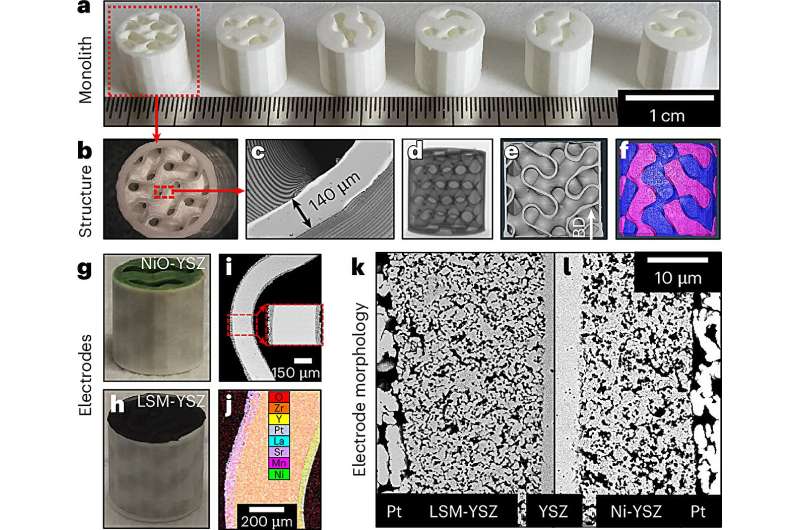

The monolithic gyrodial SOCs developed by Prof. Esposito and his colleagues have three primary components: a dense ceramic electrolyte, a porous fuel electrode and a porous oxygen electrode. Like other SOCs, they can operate in two different modes, namely as fuel cells or as electrolyzers.

“In the fuel cell (SOFC) mode, the cell generates electricity using fuel gases such as H₂, CH₄, and CO, normally called X to Power,” said Prof. Esposito. “In the electrolysis (SOEC) mode, it produces fuel gases and O₂ by electrolyzing H₂O or CO₂, called Power to X.”

To fabricate their 3D SOCs, the researchers first realized their monolithic ceramic frame, which includes an electrolyte, the sealing and support structure. This entire structure was manufactured using 3D printing technology.

Subsequently, they coated the fuel electrode and oxygen electrode on the electrolyte’s surfaces. Finally, they co-sintered the electrolyte, fuel electrode and oxygen electrode together, ultimately attaining a functioning monolithic gyroid SOC.

“Compared to conventional SOC stack technology, the 3D-SOC has an extremely simplified manufacturing process,” explained Dr. Zhipeng Zhou, lead author of the paper. “A conventional SOC stack requires the integration of numerous components, including single cells, metallic interconnects, and sealants. In contrast, the 3D-SOC can be fabricated using only 3D printing, coating, and co-sintering processes.”

In contrast with 2D SOCs, the 3D device developed by the researchers can be scaled up without the need for additional components, which in turn reduces its overall weight. In addition, the team’s new design enables greater space for the electrolyte, while minimizing the cell’s size and maximizing its compactness.

“The 3D-SOC is flexible and could be upscaled without metallic interconnects,” said Dr. Zhou. “The complete elimination of metallic interconnects significantly improved the stability of the SOC system and reduced its cost.”

The recent work by Prof. Esposito, Dr. Zhou and their colleagues opens new exciting possibilities for the fabrication of 3D SOCs. In the future, the devices they designed could be improved further and deployed in various settings, particularly within the aerospace and automotive industries.

“Some examples include NASA’s Mars program and Airbus’ SOFC aircraft (HYLENA | Airbus),” said Dr. Venkata Nadimpalli, corresponding author of the paper. “From a scientific perspective, the 3D-SOC features fundamentally different structures compared to conventional SOC designs. As a result, conclusions drawn from traditional SOCs may not apply to 3D-SOCs, due to their distinct gas distribution and heat transport properties.”

Prof. Esposito, Dr. Zhou and Dr. Nadimpalli hope that their study will soon inspire other research groups to design similar 3D SOCs that are compact, highly performing and more scalable.

Written for you by our author Ingrid Fadelli,

edited by Gaby Clark, and fact-checked and reviewed by Robert Egan—this article is the result of careful human work. We rely on readers like you to keep independent science journalism alive.

If this reporting matters to you,

please consider a donation (especially monthly).

You’ll get an ad-free account as a thank-you.

More information:

Zhipeng Zhou et al, Monolithic gyroidal solid oxide cells by additive manufacturing, Nature Energy (2025). DOI: 10.1038/s41560-025-01811-y.

© 2025 Science X Network

Citation:

3D-printed gyroidal solid oxide cells offer lighter, more compact energy solutions (2025, August 20)

retrieved 20 August 2025

from https://techxplore.com/news/2025-08-3d-gyroidal-solid-oxide-cells.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.