Tin-halide perovskites, a class of tin-based materials with a characteristic crystal structure that resembles that of the compound calcium titanate, could be promising alternatives to commonly used semiconductors. Past studies have explored the possibility of using these materials to fabricate p-channel thin-film transistors (TFTs), devices used to control and amplify the flow of charge carriers in electronics devices.

So far, however, the reliable fabrication and integration of thin-film perovskites into commercially available electronics has proved challenging. This is in part due to difficulties encountered when trying to produce uniform perovskite films with consistent electronic properties using scalable and industry-compatible methods.

Researchers at Pohang University of Science and Technology recently introduced a new promising strategy for the fabrication of highly performing TFTs based on tin-halide perovskites. Their approach, outlined in a paper published in Nature Electronics, relies on thermal evaporation and the use of lead chloride (PbCl2) as a reaction initiator.

“Our recent publication explores the transition from solution-processed to vapor-deposited tin-halide perovskites for p-channel transistors,” Prof. Yong-Young Noh, senior author of the paper, told Tech Xplore. “Building on years of work optimizing high hole mobility through solution-based methods, we now address the pressing challenge of aligning perovskite semiconductors with industry-standard manufacturing. For example, the OLED industry is already manufacturing 8th-generation displays with substrate sizes exceeding 2 m x 2 m using a thermal evaporation process.”

As part of their research, Prof. Noh and his colleagues compared the performance of solution-processing and vapor-deposition techniques for the fabrication of reliable tin-halide perovskite TFTs. This comparison allowed them to identify key parameters that contribute to the realization of high-quality, vapor-deposited tin perovskite films with suitable hole densities and mobilities.

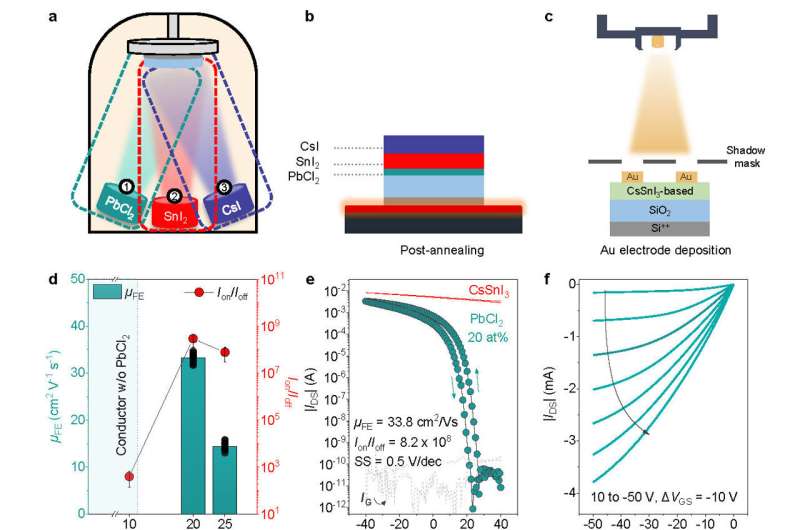

Based on these parameters, the researchers devised a new approach to fabricate highly performing tin perovskite TFTs. Their proposed strategy entails the use of vapor deposition to sequentially deposit PbCl2, tin iodide (SnI2), and cesium iodide (CsI) onto a substrate.

“While the combination of these starting precursors forms cesium-tin-iodide (CsSnI3)-based perovskites, the PbCl2 deposited as the most underlying layer serve as a key deposition technique for fabricating high-quality films,” explained Prof. Noh. “The volatile chloride initiates solid-state reactions that drive the transformation of the as-deposited precursor materials. This process promotes the formation of uniform, high-quality perovskite films while also tuning the hole density to levels suitable for use as transistor channel layers.”

The recent work by Prof. Noh and colleagues could represent a significant step towards the large-scale development of tin-halide TFTs via vapor deposition. Firstly, the team showed that when used as an additive PbCl2 successfully initiates solid-state reactions, enabling the formation of high-quality perovskite films.

“In addition, our optimized p-channel transistors achieved excellent performance, with average hole mobilities of 33.8 cm2/Vs and on/off current ratios around 108, comparable to—and in some aspects, surpassing—solution-processed devices,” said Prof. Noh.

“Although the fabrication of perovskite transistors using a deposition process has been reported previously, the mobility was very low at less than 1 cm2/Vs , so it was far from the commercialization level. Finally, our vapor-deposited transistors demonstrated significantly improved stability, marking a major advancement toward practical and scalable applications.”

The researchers used their proposed strategy to develop new transistors, which they then tested and compared to other transistors commonly integrated in organic light-emitting diodes (OLEDs). They found that their transistors significantly outperformed IGZO-based oxide transistors that are currently commercialized as OLED driving circuits.

Prof. Noh and his colleagues predict that their p-type TFTs could both improve the performance and reduce the power consumption of OLEDs. Their study could also inspire other research groups to explore the potential of vapor deposition-based strategies for the scalable fabrication of tin-halide perovskite-based transistors. In the future, the findings gathered by this team of researchers could also open new interesting possibilities for the development of large-area, low-cost VLSI (very large-scale integration) electronics and vertically stacked circuit architectures.

“With the successful vapor-deposition of high-quality tin-halide perovskite films, our future research will focus on two key areas: advanced materials engineering and device integration,” said Prof. Noh. “On the materials side, we aim to explore new compositional variations to enable lower-temperature processing, while refining control over device parameters such as turn-on voltage and hysteresis for reliable operation.”

The researchers are now working on perfecting the vapor deposition process employed in their recent study and further validating its potential. In addition, they soon hope to broaden the fields in which the resulting transistors could be applied, by increasing their hole mobility and current on/off ratio.

“On the application side, vapor-deposition opens the door to vertical stacking of perovskite layers, paving the way for more complex circuit architectures without relying on solvent-based photolithography,” added Prof. Noh. “These directions offer exciting opportunities to push the boundaries of perovskite-based electronics.”

More information:

Youjin Reo et al, Vapour-deposited high-performance tin perovskite transistors, Nature Electronics (2025). DOI: 10.1038/s41928-025-01380-8.

© 2025 Science X Network

Citation:

A new strategy to fabricate highly performing thin-film tin perovskite transistors (2025, May 17)

retrieved 17 May 2025

from https://techxplore.com/news/2025-05-strategy-fabricate-highly-thin-tin.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.