Using a blend of forensic material analysis with experimental archaeology, researchers have successfully reconstructed the techniques and processes behind crafting the Nebra Sky Disc.

The Nebra Sky Disc is a bronze, disc-shaped object, first discovered in 1999 on Mittelberg Hill near Nebra, Germany. It features a blue-green patina and is inlaid with gold symbols representing the Sun or full moon, a crescent moon, and stars.

According to archaeologists, the disc dates from between 1800 to 1600 BC and is attributed to the Early Bronze Age Únětice culture.

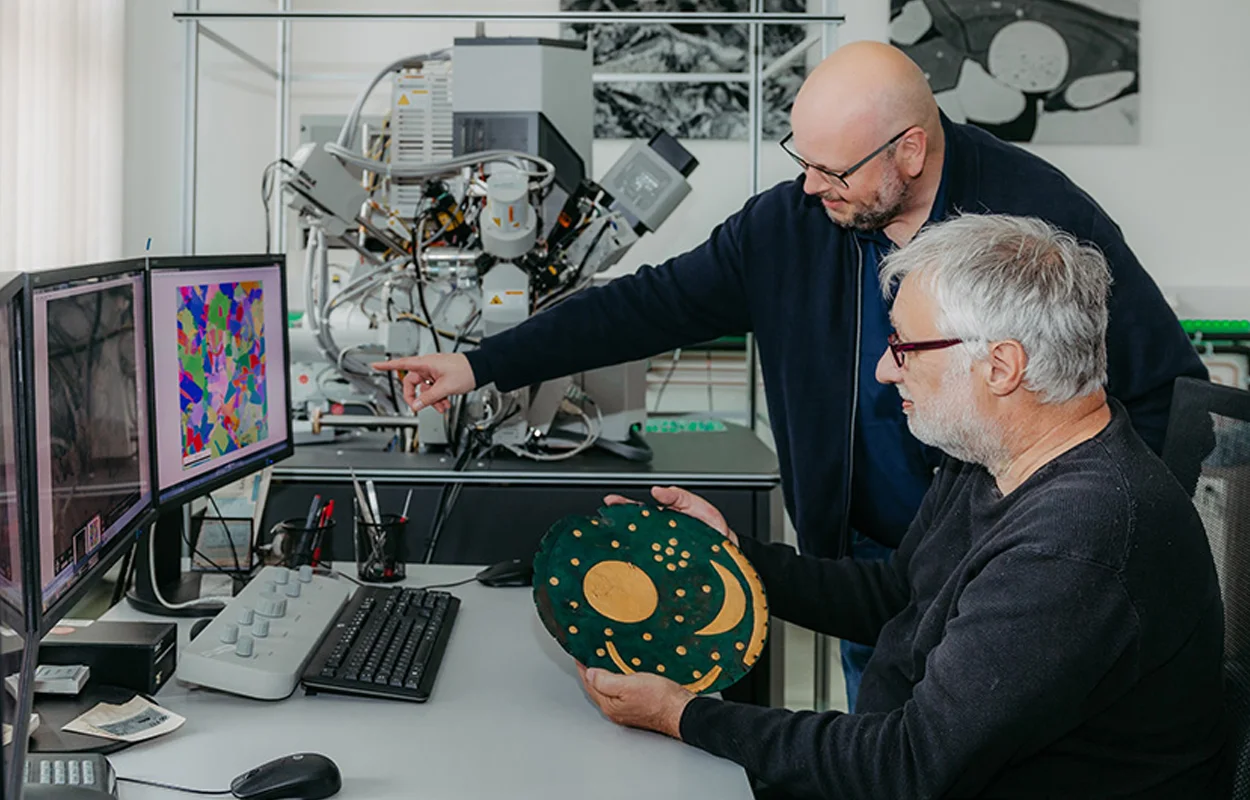

Experts from Guericke University Magdeburg, working in collaboration with the State Office for Monument Preservation and Archaeology of Saxony-Anhalt, analysed the crystalline structure of the metal using state-of-the-art electron backscattering and scanning electron microscopy.

Prof. Thorsten Halle, said: “We scan the surface of the metal with the electron beam, which results in a backscattering effect of the electrons that depends on the material configuration. In other words, it is something like a fingerprint of the smallest components of the material under investigation.”

“Depending on the crystallographic direction in which the grains are oriented, their size and whether they are deformed, we can draw conclusions about the manufacturing process.”

According to the study, the disc was cast at temperatures exceeding 1200°C, then repeatedly reheated to approximately 700°C and reshaped multiple times.

“We’re conducting what we might call metallurgical forensics, peering into the disk’s past as if it were a metallurgical diary”. What is especially remarkable, Halle added, is that the Sky Disk was created without written knowledge, measuring instruments, or formal theory, only through trial and error.

A truly crucial partner in the joint project was coppersmith Herbert Bauer, who produced replicas of the disc under conditions conceivable in the Bronze Age, including stone hammers and charcoal kilns.

“These replicas were then examined and compared in the laboratory, just like the original, under the microscope. This provided unequivocal evidence of the manufacturing process. “By comparing the microstructure of the replicas and the original, we were able to identify temperature gradients, forming steps, and even production errors,” said the study authors.

Header Image Credit : Otto von Guericke University Magdeburg

Sources : Otto von Guericke University Magdeburg