Microrobots, small robotic systems that are less than 1 centimeter (cm) in size, could tackle some real-world tasks that cannot be completed by bigger robots. For instance, they could be used to monitor confined spaces and remote natural environments, to deliver drugs or to diagnose diseases or other medical conditions.

Researchers at Seoul National University recently introduced new modular and durable microrobots that can adapt to their surroundings, effectively navigating a range of environments. These tiny robots, introduced in a paper published in Advanced Materials, can be fabricated using 3D printing technology.

“Microrobots, with their insect-like size, are expected to make contributions in fields where conventional robots have struggled to operate,” Won Jun Song, first author of the paper, told Tech Xplore. “However, most microrobots developed to date have been highly specialized, tailored for very specific purposes, making them difficult to deploy across diverse environments and applications. Our goal was to present a new approach toward creating general-purpose microrobots.”

While developing their microrobots, Song and his colleagues drew inspiration from drones—unmanned aerial vehicles (UAVs)—which can be tailored for a wide range of applications (e.g., photography/videography, package delivery, defense, etc.). Their objective was thus to develop adaptive microrobots that could be applied to different real-world problems.

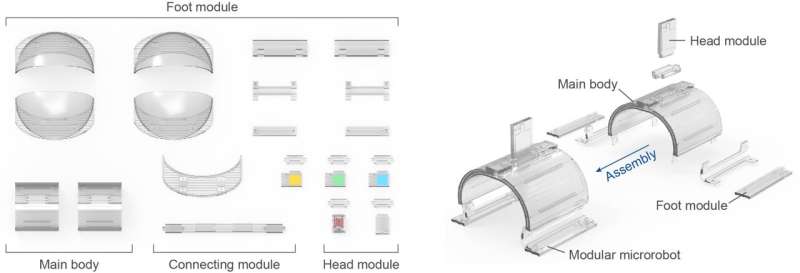

“Our microrobot is composed of a main body and three types of modules,” explained Song. “The main body serves as the hub where all other modules are attached and is responsible for controlling the overall movement of the robot. The foot modules allow the microrobot to walk, not only on flat surfaces, but also on sand and even across water. The head modules enable real-time interaction with nearby robots or humans. Finally, the connecting modules make it possible for multiple microrobots to collaborate and operate together as if they were a single unit.”

To fabricate their microrobots’ individual components, the researchers used a custom-made multi-material 3D printer that they had created as part of their earlier studies. Notably, this 3D printer would enable the efficient mass-production of microrobot modules, allowing manufacturers to print up to eight identical units in a single run.

The team’s 3D-printing approach also makes it easy to tailor robots for specific tasks, by enabling the fabrication of specific modules or components on-demand to broaden their functionalities. In initial tests, the microrobots created by the researchers were found to reliably move in different settings, walking on smooth, rough and granular terrains, but also swimming in aquatic environments.

“Many researchers have focused on developing microrobots optimized for very specific purposes, and this approach has greatly contributed to creating highly efficient robots with excellent performance,” said Song. “However, for microrobots to reach commercialization—similar to how drones or Boston Dynamics’ Spot are now widely used in daily life—they must be capable of operating across a broader range of environments and applications.”

In the future, the modular microrobot design introduced by Song and his colleagues and their 3D printing strategy could contribute to the large-scale fabrication of tiny robotic systems tailored for specific purposes. Meanwhile, other research groups could draw inspiration from the team’s paper to develop other customizable microrobots that can operate in different environments.

“We now aim to use our newly developed multi-material printing technology and high-performance photocurable materials to develop other advanced robots and devices,” added Song.

Written for you by our author Ingrid Fadelli, edited by Stephanie Baum, and fact-checked and reviewed by Robert Egan—this article is the result of careful human work. We rely on readers like you to keep independent science journalism alive.

If this reporting matters to you,

please consider a donation (especially monthly).

You’ll get an ad-free account as a thank-you.

More information:

Won Jun Song et al, All‐3D‐Printed Multi‐Environment Modular Microrobots Powered by Large‐Displacement Dielectric Elastomer Microactuators, Advanced Materials (2025). DOI: 10.1002/adma.202507503

© 2025 Science X Network

Citation:

3D-printed microrobots adapt to diverse environments with modular design (2025, October 16)

retrieved 16 October 2025

from https://techxplore.com/news/2025-10-3d-microrobots-diverse-environments-modular.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.