Researchers at Seoul National University have unveiled a thermal management technology capable of selectively implementing cooling and heating functions using a single material and process, without requiring electricity.

The technology developed by Professor Seung Hwan Ko’s research team in the Department of Mechanical Engineering at SNU is drawing attention as an innovative solution that replaces existing complex processes. It enables the same transparent silicon polymer material to be processed into either a cooling or heating surface simply by adjusting the intensity of laser output, without consuming electricity.

The paper, titled “Monolithic Integration of Radiative Cooling and Solar Heating Functionalities by Laser-induced Pyrolysis,” is published in the journal Joule.

As the necessity to address climate change and the severity of the energy crisis grow, “zero-energy” thermal management technologies that regulate temperature using sunlight and radiant heat without consuming additional electricity are emerging as a new alternative. For example, they create a cool environment in summer by reflecting sunlight and emitting radiant heat, while absorbing sunlight to maintain warmth in winter.

However, until now, this technology has faced limitations in practical application to daily life or industrial settings, as cooling and heating functions could only be achieved using different materials and complex processes. Therefore, in the current reality where roads and buildings absorb excessive heat in midsummer, causing air conditioning costs to skyrocket, and where massive energy is consumed for heating in winter, a technology that can implement either cooling or heating functions as needed using a single material—unlike previous thermal management technologies—could be a highly useful breakthrough.

The research team developing this technology proposed a novel material processing technique involving laser irradiation of a transparent silicon polymer called “PDMS (Polydimethylsiloxane).” This technology is based on a simple principle: the material’s optical and thermal properties change depending on the laser’s output intensity. For example, when exposed to a high-power laser, the PDMS surface transforms into a “white porous structure (SiO2-centered),” reflecting sunlight and emitting heat outward to perform a cooling function.

Conversely, using a low-power laser creates a “black porous structure (SiC-centered),” which absorbs sunlight and performs heating. In other words, this is the world’s first technology to selectively implement cooling and heating functions by applying a single laser process to the same transparent material, varying only the output power.

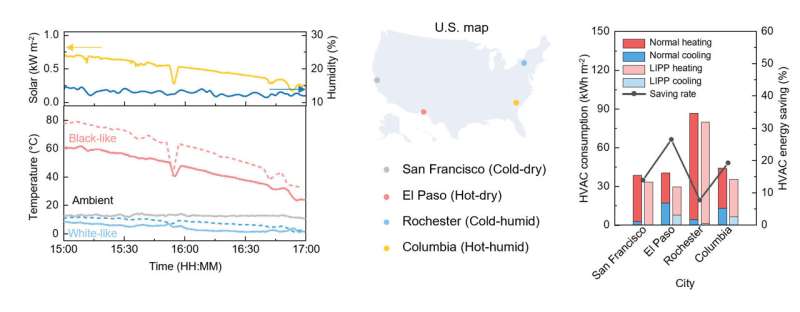

The research team demonstrated this new material’s thermal management capabilities in real outdoor environments. Even under sunlight during the day, the white porous surface maintained an average temperature 5.89°C lower than the external environment, while the black porous surface self-heated to 58.1°C, proving its outstanding thermal control performance. Furthermore, building energy simulations considering various climate conditions showed that applying this material to building roofs could reduce annual heating and cooling energy costs by up to 26.5%.

This technology not only enables cooling and heating functions without electricity but also demonstrates the potential to expand into “plus-energy” technology that simultaneously utilizes both functions to generate electricity. For instance, the thermal difference generated between a white cooling surface and a black heating surface can be harnessed to create solar-based thermoelectric generators that automatically produce electricity. Furthermore, the heating function can be applied to various energy applications, such as water harvesting (desalination) systems that use solar energy to evaporate seawater and collect the resulting freshwater.

The technology developed by the research team is significant in that it greatly enhances the practicality and scalability of existing thermal management technologies. This is because it enables the low-cost implementation of both cooling and heating functions using a single material and a single process equipment (laser equipment), eliminating the need to prepare different materials or processes for different functions. Therefore, this technology is expected to find wide application in various eco-friendly energy fields, such as improving the heating and cooling efficiency of buildings, ensuring the thermal stability of outdoor devices, and generating electricity using solar power.

Professor Seung Hwan Ko stated, “This technology presents a new paradigm in thermal management by opening the path to freely implement both cooling and heating using a single material without complex manufacturing processes. It will become a foundational technology applicable to diverse industrial fields such as building exterior materials, outdoor electronic devices, and energy harvesting.”

More information:

Yeongju Jung et al, Monolithic integration of radiative cooling and solar heating functionalities by laser-induced pyrolysis, Joule (2025). DOI: 10.1016/j.joule.2025.102007

Citation:

Laser-tuned polymer surface switches between cooling and heating modes without consuming electricity (2025, October 14)

retrieved 14 October 2025

from https://techxplore.com/news/2025-10-laser-tuned-polymer-surface-cooling.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.