Research from the University of Liverpool has highlighted weaknesses in the structural design of hot water bottles. Hot water bottles have been around for generations, yet there is surprisingly little research into how they respond to external forces. However, increased reports of sudden ruptures causing burns prompted a research team from the University’s School of Engineering to take a closer look.

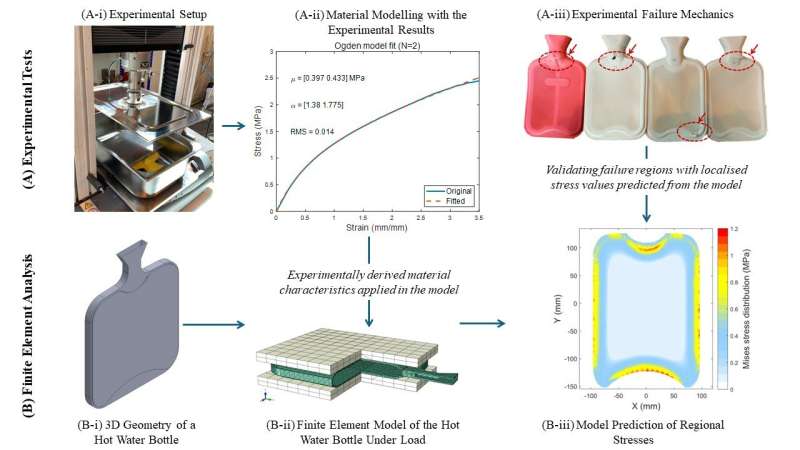

In the first study of its kind, the researchers analyzed hot water bottle failures using a combination of real-world compression tests and computer simulations.

Their study, published in Applied Sciences, reveals structural weaknesses that could lead to unexpected bursts and leaks, with the neck and edges being especially prone to failure.

Most hot water bottles are made using vulcanized rubber due to its flexibility, durability, and resistance to higher fluid temperatures.

Researchers experimentally tested identical brand-new rubber bottles produced by the same manufacturer and filled to two-thirds of their capacity.

In the Materials Laboratory at the School of Engineering, the bottles were tested to evaluate how well they maintained their structural integrity when subjected to gradually increasing external load.

The team then simulated the forces acting on the hot water bottles under pressure using advanced finite-element modeling.

In addition, tensile test strips were cut from the central area of a hot water bottle and tested to measure their mechanical properties, including elasticity, strength, and resistance to stretching. This helped determine how material properties contributed to bottle failures under stress.

The precise simulation work showed that stress levels peaked in the neck area, supporting what was observed in the lab. The seam and cap area experienced the most strain, increasing the risk of sudden failure.

This simulation shows the weak areas of the current hot water bottle design are the neck and the edges, which was confirmed by experimental testing.

Dr. Ahmed Abass, lecturer in Biomedical Engineering at the University of Liverpool, said, “For hot water bottle users, the message from our study is clear: avoid putting excessive weight on a filled hot water bottle, especially while sleeping, as compression significantly raises the likelihood of rupture, which could lead to serious burns.

“For manufacturers, the research highlights the need to rethink bottle geometry design. Reinforcing the neck and seam areas could improve durability and make these bottles safer for consumers.

“While this study significantly enhances our understanding of hot water bottle mechanics, it also shows that even the simplest everyday products need careful engineering to prevent injury.”

The research team was led by Dr. Abass and involved Master’s and Ph.D. students from the School of Engineering at the University of Liverpool.

More information:

Joseph Towler et al, Preliminary Failure Analyses of Loaded Hot Water Bottles, Applied Sciences (2024). DOI: 10.3390/app14114427

Citation:

Pinpointing weaknesses in hot water bottle design (2025, March 14)

retrieved 14 March 2025

from https://techxplore.com/news/2025-03-weaknesses-hot-bottle.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.