Battery technology researchers at Worcester Polytechnic Institute (WPI) recently published studies that address some of the biggest challenges in the field.

Led by Professor Yan Wang, William B. Smith Professor of Mechanical and Materials Engineering, the studies published in Joule and Materials Today focus on improving the performance and stability of all-solid-state lithium batteries and on ways to recycle lithium-metal batteries safely and efficiently.

Safe and scalable lithium-metal battery recycling

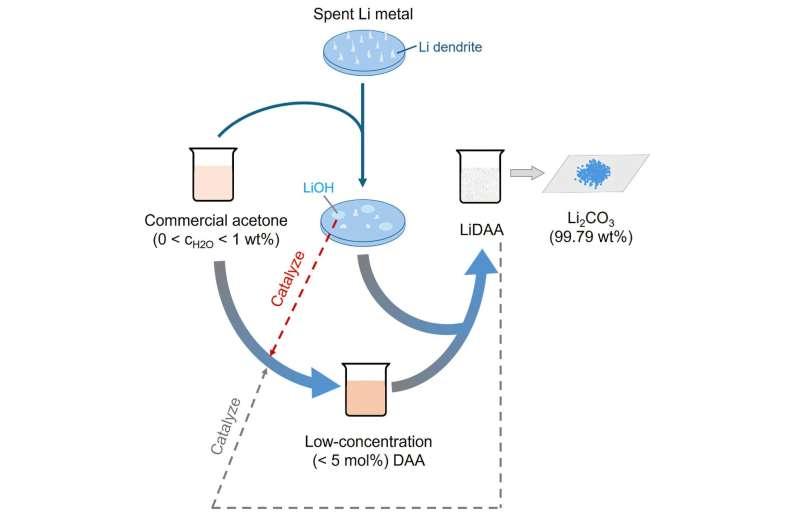

In the Joule article Wang’s team reports a safe, scalable, and economically viable method for recycling highly reactive lithium-metal anodes. By using a “self-driven” aldol condensation reaction in commercial acetone, the researchers converted spent lithium-metal anodes into lithium carbonate (Li₂CO₃) at 99.79% purity—surpassing industry standards for battery-grade materials.

The recovered lithium carbonate was then used to produce new cathode materials with electrochemical performance comparable to commercial counterparts, demonstrating real-world feasibility. This breakthrough offers a pathway to reduce dependence on mining while lowering costs and accelerating the adoption of cleaner technologies.

“This method is an effective solution to one of the most pressing challenges in the battery industry,” said Wang. “By turning a safety liability into a driving force for recovery, we’ve created a process that is both practical for industry adoption and critical for building a more sustainable energy future.”

Advancing solid-state battery design

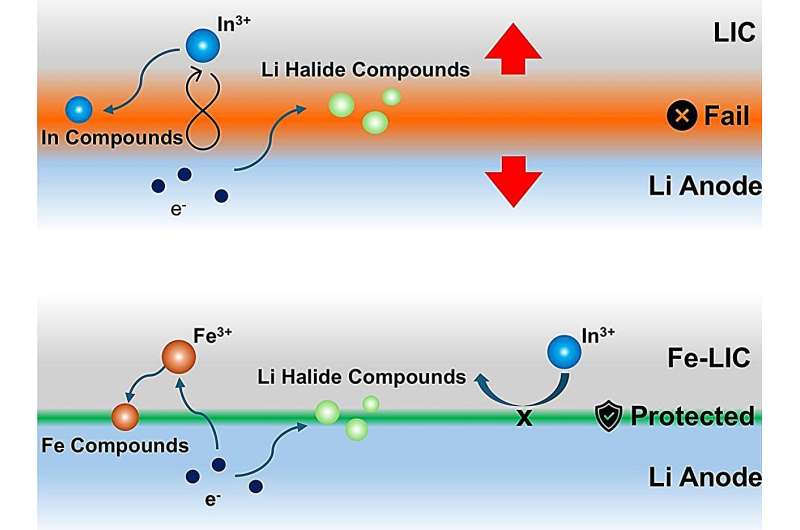

The research team’s work published in Materials Today tackles another barrier to next-generation batteries: the poor compatibility of halide-based solid-state electrolytes with lithium-metal anodes. Traditionally, these systems require protective interlayers that add cost and complexity.

The WPI team introduced iron doping into lithium-indium chloride, creating a material that achieves direct and stable contact with lithium-indium anodes without the need for a protective layer. The material retained high ionic conductivity and delivered long-term performance, with full cells cycling more than 300 times at 80% capacity retention and symmetric cells operating for over 500 hours—the first such demonstration in the field.

“This work establishes iron doping as an effective strategy to simplify solid-state battery design while enhancing stability and performance,” said Wang. “Together with our recycling research, these findings represent important steps toward a future where high-performance lithium batteries are not only more powerful but also safer and more sustainable.”

By tackling both the beginning and end of the battery life cycle—from safer designs to scalable recycling—WPI researchers are advancing the technologies needed for the next era of electric vehicles, portable electronics, and renewable energy storage.

More information:

Self-driven aldol condensation enabling high-purity Li2CO3 recovery from spent lithium metal anodes, Joule (2025). DOI: 10.1016/j.joule.2025.102136. www.cell.com/joule/fulltext/S2542-4351(25)00317-4

Jinzhao Fu et al, In-situ formation of stable interface towards Li-in anode for halide solid-state electrolyte, Materials Today (2025). DOI: 10.1016/j.mattod.2025.08.038

Citation:

Researchers pioneer advances to make next-generation lithium batteries safer (2025, September 22)

retrieved 22 September 2025

from https://techxplore.com/news/2025-09-advances-generation-lithium-batteries-safer.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.